Capable and Versatile

LS-1881

The LS-1881 consists of a Windows® based controller unit that can handle up to 8 independent pneumatic units to achieve high speed production rates. This leak test package can also be used to simultaneously test multiple cavities on a single production part. Utilizing the same patented differential pressure sensor (DPS) as the LS-1842 air leak tester, the LS-1881 unit allows for a wide variety of quality control functions, as well as simple operation, all viewed and controlled from a large, full-color touch Panel LCD.

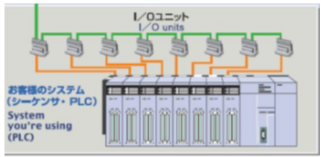

Multiple pneumatic circuit units

With the ability to connect up to 8 units, the LS-1881 reduces facility costs and the space required to operate. This allows for maximum efficiency and productivity in a limited space.

Simple wiring

Thanks to the simplicity of the wiring, the LS-1881 greatly reduces the number of machine building hours. In addition, it allows I/O units to be installed directly on the control board, providing a simple connection between the pneumatic circuit units.

Selective measurement screen

The LS-1881 allows the selection of different types of display such as offset value, test pressures and others, as well as the leakage value. Different modes accomplish this feature, giving the user the ability to select one, two, four or eight measurements as one time.

Substantial help mode

The help mode content allows the user to display lists of errors and probable causes to narrow down the source of the problem. When the LS-1881 exhibits a fault, it instantly checks the status of the input and output signals on the I/O monitor screen.

Quality control functions

El LS-1881 allows up to 1000 data values per station and can be plotted directly on the machine with the quality control (QC) function. Then, the measured data can be analyzed using a computer for further understanding and manipulation via a USB device.

Product features

Standard features

Intelligent pneumatic circuit II

Load retention

Calibration

Leakage limits

Drift compensation

Self-diagnosis

Exhaust interference prevention

Sensor protection (exhaust air blowing)

Sensor protection (external exhaust valve)

Group

Checking valve performance

Pneumatics Checking the sensitivity of the DPS

Valve Equipment

Weight savings

High flow capacity

It is used to detect the location of the leak

Equivalent internal volume measurement

K (Ve) Range calibration and compensation of differential pressure sensor

Range calibration and pressure sensor compensation test

Two-level limit setting (DET HH, DET Hi, DET Lo, DET LL)

Noise reduction

Mastering

the average

landline mobile

Valve performance

Pneumatics DPS Sensitivity

Shut-off valve open/closed

Sensor compensation

CPU performance

Control of the exhaust timing of the pneumatic circuit units

Cleaning of the pneumatic circuit at the end of each test cycle

A separate external exhaust valve unit (G3-M) is required

Synchronize start and end (escape) of selected station

General specifications

Differential pressure

Minimum reading

Reading accuracy

Sensor range

Test pressure

0,1 Pa

± 2,5% of the reading± 1 Pa

± 2,5% de la lectura ± 1 Pa for a range greater than 50 Pa

± 2 Pa for a range of 0-50 Pa

± 1500 Pa

5 mPa

Screen

Test accuracy

Leakage rate

Equivalent internal volume

mPa, kPa (PSI, kg / cm2, bar, mbar, mmHg, cmHg, inHg) * 1

Pa, kPa, mL / s, mL / min, L / min

(mmH20, inH20, mmHg, in3 / min, in3 / d) * 1

mL, L (in3, ft3) * 1

Number of stations

Up to 8 stations

Number of channels

32 channels (0 ~ 31)